-

Email Support

sales@maniks.com -

Call Support

+91-9823118714

INTRODUCTION

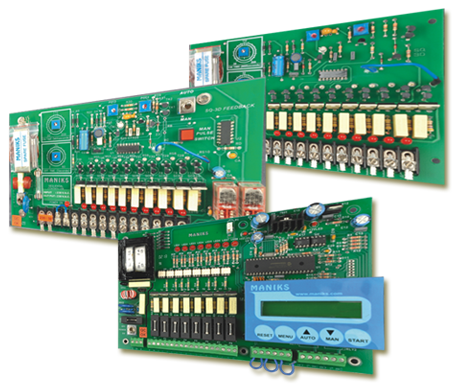

Maniks is the most reputed Indian brand with a history of 30 years for manufacturing reverse jet pulse valves used in bag-filter applications and the sequential timers used in conjunction with them. These are used in dust collector equipment for cement, steel and such other industries. The company was started by Mr. Shekhar Kulkarni, an IIT Mumbai alumnus, with a vision to substitute imported products with Indian make products. The primary aim was to produce reliable products with excellent quality and service.

We are an ISO 9001:2015 certified organization. Our quality policy states that priority is to exceed the “demands and expectations” of our customers and aim for repeat orders and customer loyalty. Thus “Brand loyalty” is the highlight of our organization which drives us for continuous improvement.

Many of our customers - OEMs, cement manufacturers and other end users such as chemical and food industries have expressed their complete satisfaction regarding the performance of our products for their bag filters. No wonder these users have been repeatedly buying products and their spares from us to meet their new as well as replacement requirements. This has encouraged us to streamline our manufacturing process to meet bulk requirements. Our primary objective is to cater to our customers' requirements in fastest possible manner without compromising on the quality of products. In short, we guarantee swift and efficient delivery of products that comply with international standards with respect to quality. Our delivery data shows that 75% of our orders are shipped on the same day as the receipt of payment. Also, inspite of having high quality standards, our products are available at extremely competitive prices.

We give very prompt after-sales service and our technicians have vast knowledge of not only our own products, but also the entire system. This helps in quick fault-finding at customer's site. Through years of association with us, our customers know that scientific import substitution and technical knowledge is our forte. This has prompted many of our customers to send us imported samples along with their requirements for import substitution. This has led to our market oriented growth with optimal efforts. This growth has led us to export markets as well. We have been exporting our products to Gulf countries, Bangladesh and Kenya. Our products have been standardized by them for many years.